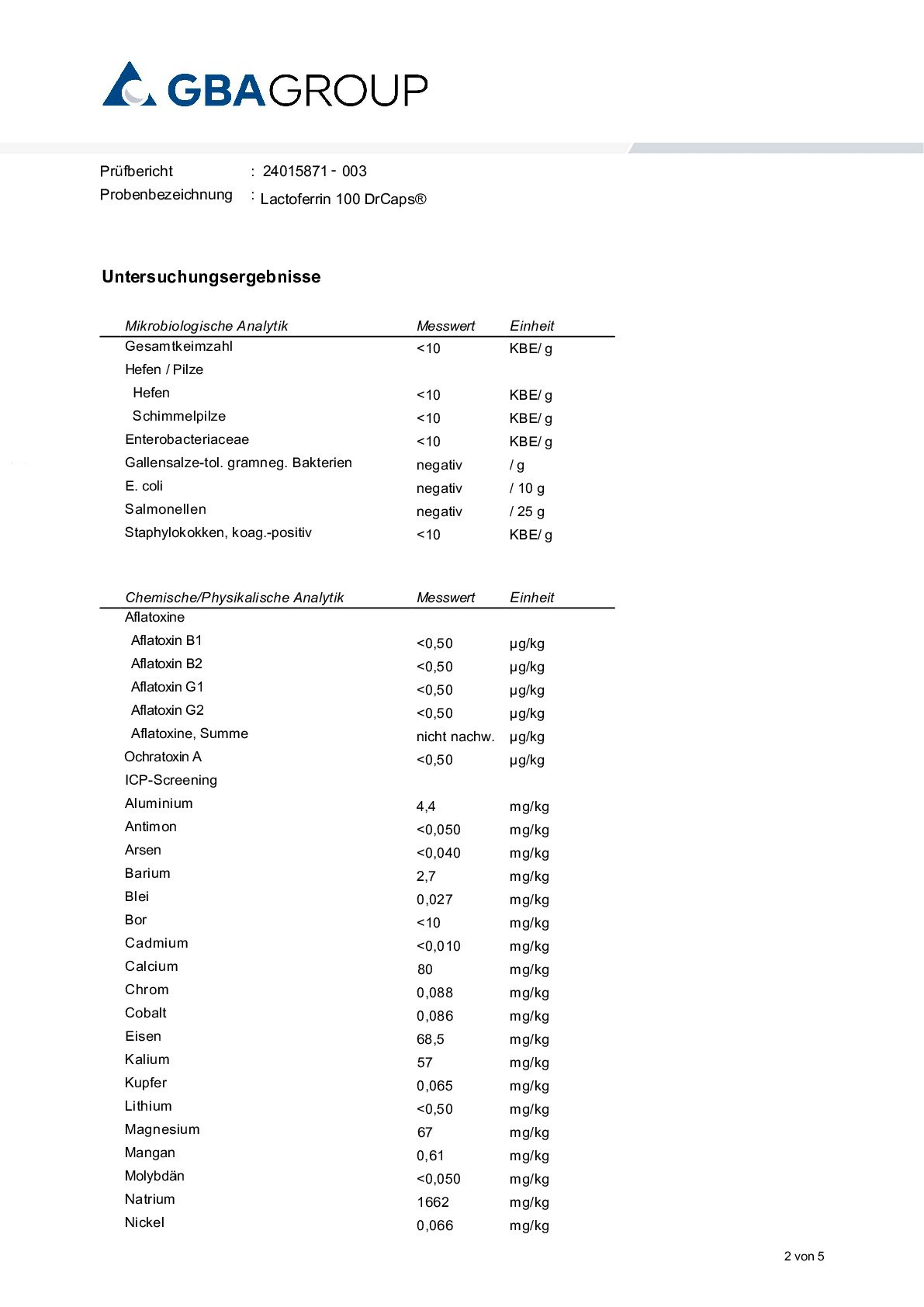

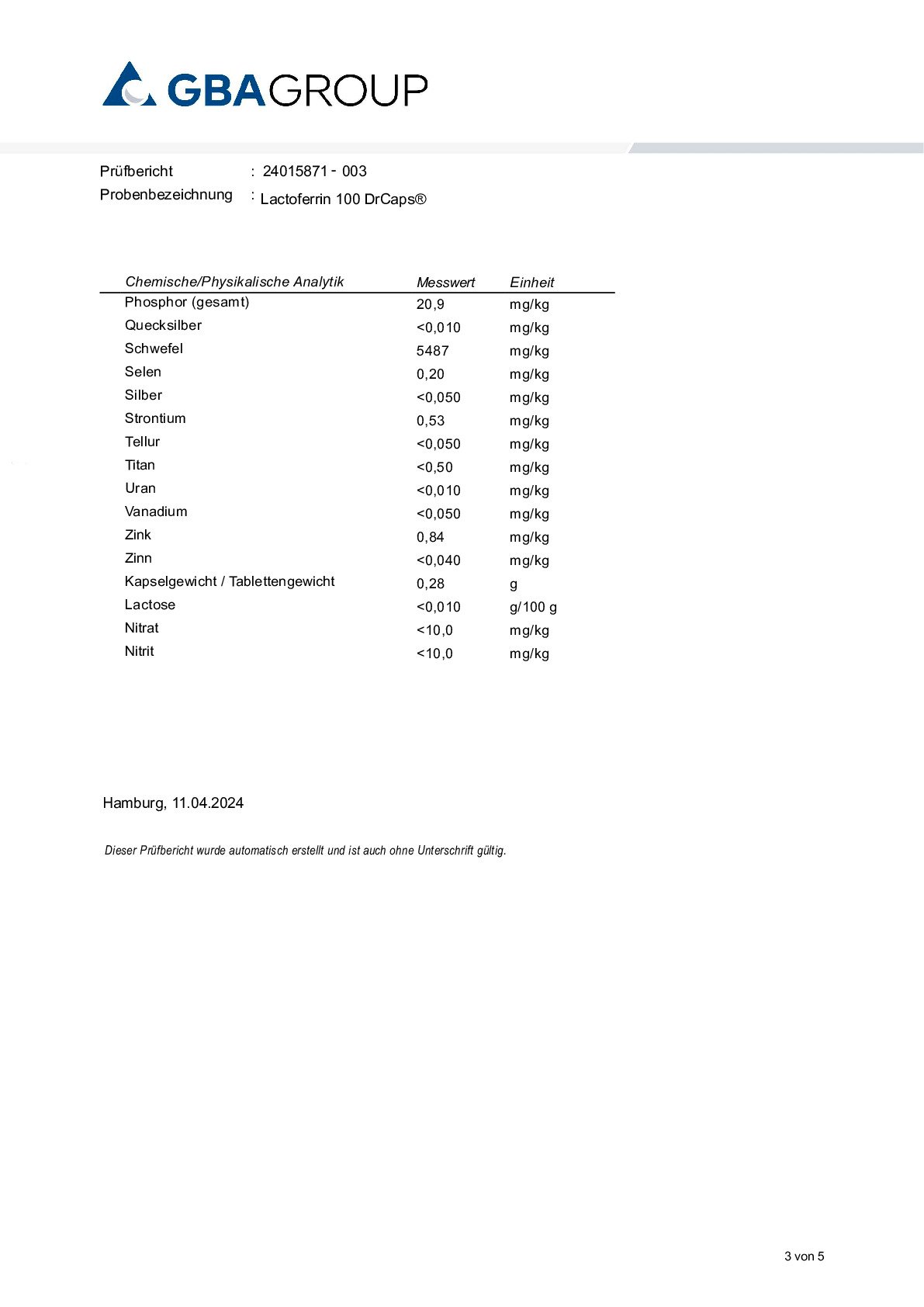

Lactoferrin is a biologically active milk or whey protein. The highest possible purity of the protein is crucial for high-quality food supplements containing lactoferrin. Our lactoferrin is efficiently isolated from cow's milk using ion exchange and ultrafiltration, resulting in an excellent purity of over 95% lactoferrin in the end product. The subsequent gentle freeze-drying process guarantees the best possible preservation of the protein. Although lactoferrin is obtained from cow's milk, our end product is considered lactose-free (less than 0.1% lactose) thanks to the efficient purification process, so that those with lactose intolerance can also consume it.

The sustainability of our products is one of our highest basic principles at Sunday. This is why we predominantly use purely vegan sources and, with very few exceptions, do not use any raw materials of animal origin. In a few cases, if we are convinced by the product and have been able to thoroughly convince ourselves of the sustainability of the sources, we include vegetarian products of animal origin in our portfolio.

The milk used for our whey protein comes from sustainable production in Australia with high standards of animal welfare. Our partner is committed to animal welfare and animal protection with their own animal welfare guidelines and a comprehensive programme. The focus here is on both the physical and mental welfare of the animals, including allowing the dairy cows to graze on pasture at least 350 days a year. In addition, special training programmes are mandatory for all employees to ensure appropriate awareness when handling the dairy cows. Special emphasis is placed on calm and low-stress handling of the animals. Other regulations include, for example, that medical examinations and treatments must be accompanied by pain-relieving measures so that the animals do not experience unnecessary suffering.

Compliance with the regulations and training programmes is ensured in annual audits. In addition, there is a constant commitment to improvements in the education and training of farmers, the development of strategies to solve problems and the improvement and definition of new standards.

We only use 100% nanoparticle-free microcrystalline cellulose as a filling material for correct dosing and filling. We use patented, gastric acid-resistant HPMC capsules (DR® Caps) as capsule shells. We then package this product in environmentally friendly amber glass.